New second generation technology

TCⅡ Series

The front end of the TCⅡ series spindle adopts double-row cylindrical roller bearing and high-speed thrust angular contact ball bearing, and the rear end is supported by double-row cylindrical roller bearing; the bed is cast in integral L-shaped 45° inclined rectangular sliding guide; with separate tailstock under hydraulic-drive telescoping; 12-position hydraulic turret and resistive type of rare lubrication system, widely used in various machining industries such as auto parts, hardware and energy.

Quick Check

Max. turning diameter:

Φ400mm

Max. turning length:

548mm

Max. spindle speed:

4500rpm

Traval range X/Z:

210/610mm

Rapid traverse X/Z:

24/30m/min

Major motor power:

11/15kW

Discover

blanc

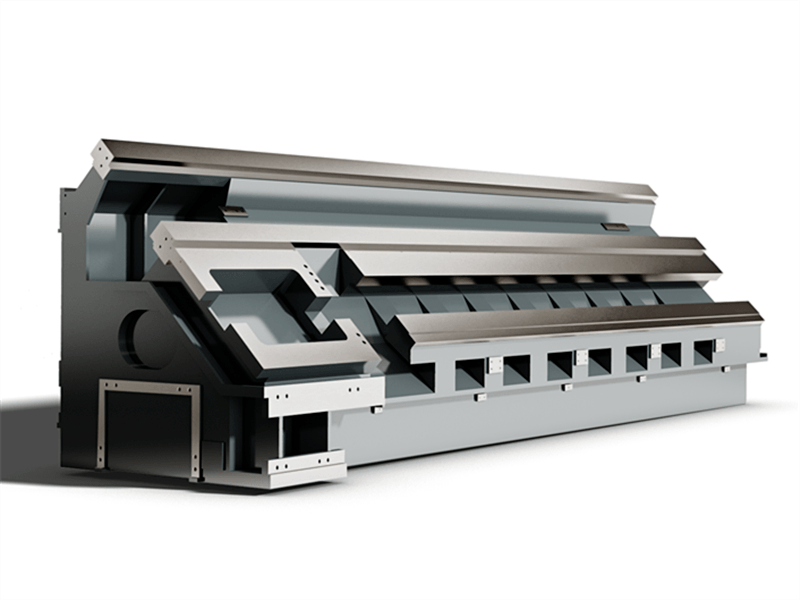

High rigidity and stability

High rigidity and stability

The integral 45° inclined L-shaped bed has high modality and shock resistance to realize the high rigidity of the lathe.

High precision retention

High precision retention

The bed and the saddle are hard rails and ground after quenching, and the sliding surface is covered with a wear-resistant soft belt to reduce friction and avoid creep, ensuring high-precision retention.

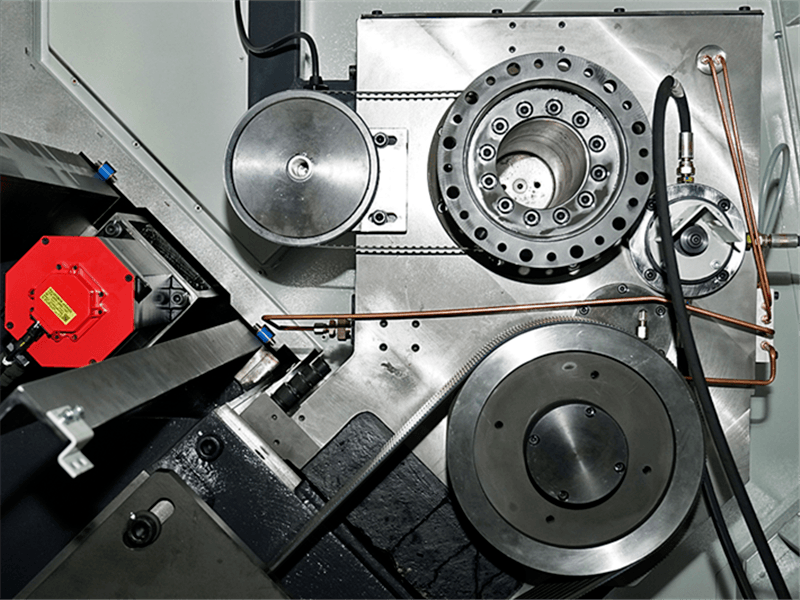

Thermal balance of spindle

Thermal balance of spindle

The spindle box and the saddle are mounted on the plane with the same angle, which reduces the distortion caused by the thermal deformation of the spindle box so as to ensure the thermal balance of the spindle.

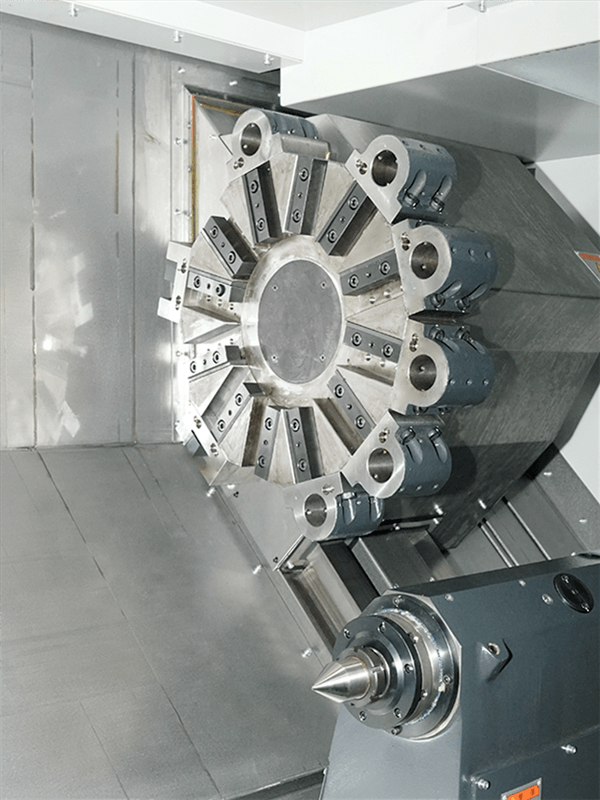

High efficiency and heavy cutting

High efficiency and heavy cutting

It has high rigidity bed and spindle and long-span hard rail, with 12-position hydraulic turret, ensuring that the machine tool has high efficiency and heavy cutting characteristics.