Precise Control: Haitian Precision Multi-Joint Robots

2024-10-20

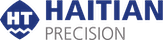

Multi-joint robots, also known as articulated robotic arms or multi-jointed robotic arms, have rotational movement in each joint, resembling the movement of a human arm. They operate with great flexibility, much like a human hand. For instance, when encountering obstacles, a multi-joint robot can maneuver around them to reach its target. It also excels in performing certain specific tasks, such as crank motion, which would be difficult for robots using polar or cylindrical coordinate systems.

Multi-joint robots are one of the most common forms of industrial robots today, widely used across various industries for automation processes. These applications include painting, assembly, welding, handling, packaging, casting, and more, significantly improving production efficiency.

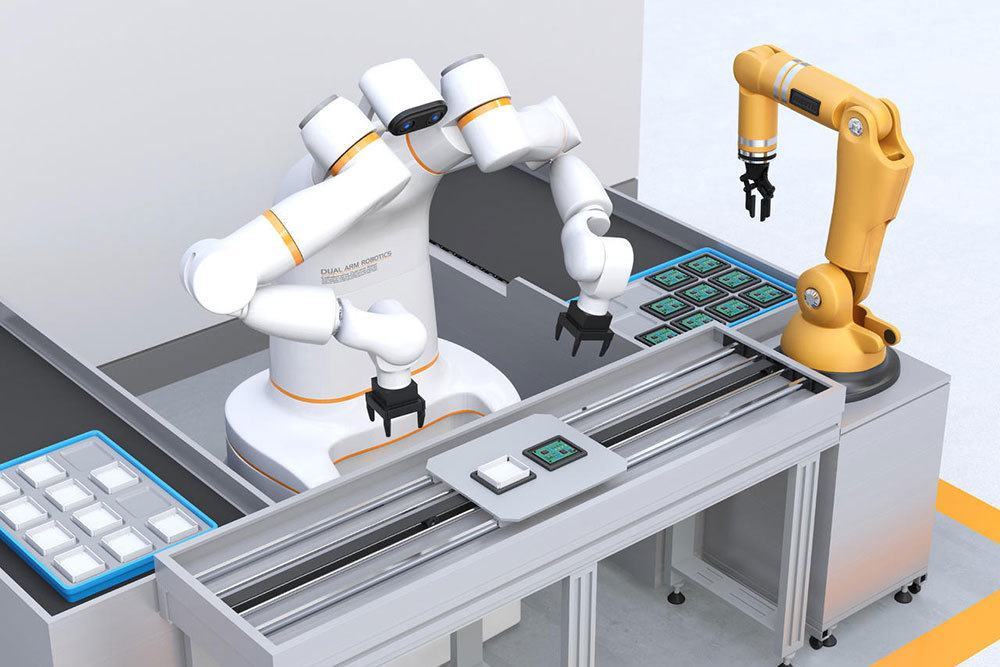

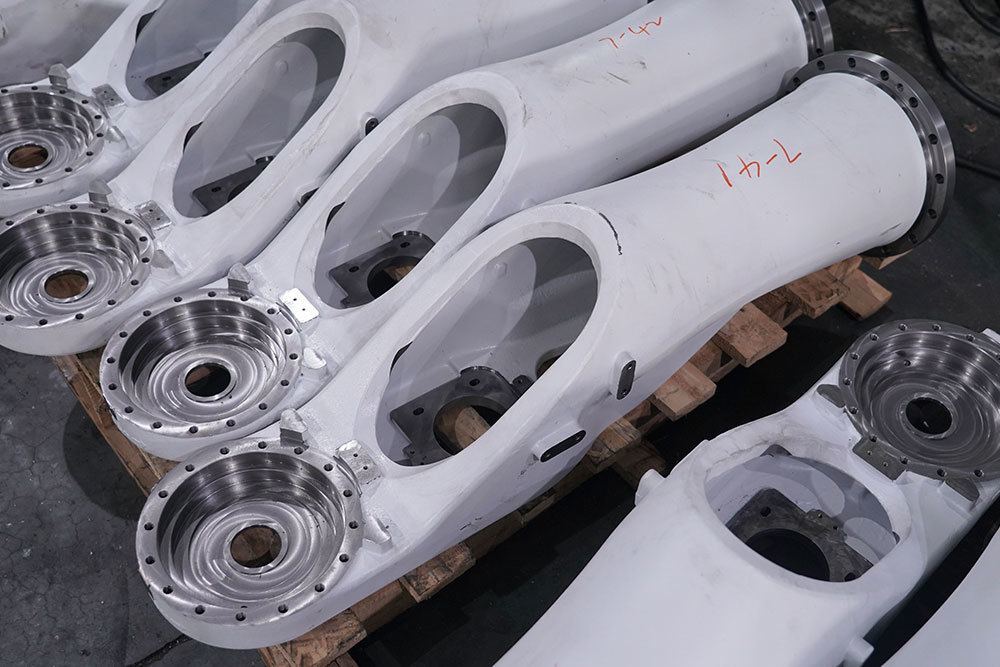

Multi-joint robots typically consist of several joints, offering high precision and speed, ideal for performing repetitive tasks with stringent accuracy requirements. Structurally, they demand compact and lightweight drive components and sensors, with an arm structure made up of wrist units, wrist connectors, forearms, bases, and RV reducers. Some elongated parts, such as wrist connectors and forearms, are particularly well-suited for production using Haitian Precision’s HPC Ⅱ and HUP series horizontal machining centers.

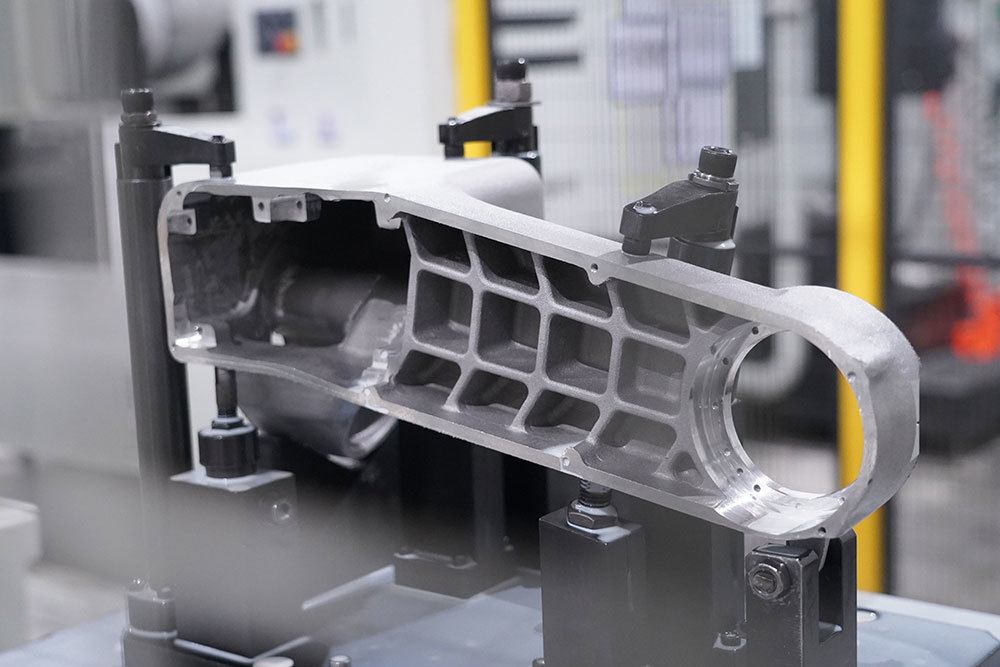

The HPC Ⅱ series horizontal machining centers from Haitian Precision feature a highly rigid base structure, heavy-duty roller guides on three axes, and an integrated high-speed spindle. They can effortlessly handle a wide range of tasks, from high-speed and high-precision operations to heavy-duty cutting, and are compatible with various materials such as aluminum, steel, and cast iron. These machines are widely applied in industries like automotive, aerospace, railways, plastic machinery, and construction machinery for precision machining tasks.

The HUP series horizontal machining centers from Haitian Precision adopt an advanced T-shaped bed structure and vertical spindle box layout, offering strong rigidity and excellent accuracy retention. Capable of machining four sides of a part in a single setup, they are particularly suitable for hole and surface machining in precision-grade box-type components.

As industrial technology continues to evolve, the future of multi-joint robots is set to move toward higher precision, greater speed, increased flexibility, and smarter solutions, with market demand expected to grow rapidly. Haitian Precision will seize this opportunity by continuously upgrading its technology and delivering competitive industry solutions, contributing to the intelligent development of industrial automation and precision manufacturing.