Customer Story: Elevating Quality Through Innovation

2024-07-16

Keda Industrial Co., Ltd. was established in 1992, focusing on building materials machinery, overseas building materials, and lithium battery materials and equipment. Its products are sold in over 70 countries and regions, making it a global leader in ceramic machinery. This issue of Haitian Precision takes you into Keda Industrial’s wholly-owned subsidiary, Foshan Keda Equipment Manufacturing Co., Ltd., to showcase the impressive performance of large gantry machining centers in structural part processing.

Keda Equipment’s smart manufacturing base in Sanshui District, Foshan City, officially started operations earlier this year. This new base is an advanced work following the introduction of extensive digital smart technology and hardware facilities by Keda Equipment. The base adopts a one flow & one-stop model, allowing large structural parts to undergo continuous operations from cutting and welding, annealing, primer sandblasting, machining, to final painting and shipment. The one-stop model ensures that the entire process for large structural parts is completed within the factory.

The first phase of Keda Equipment’s smart manufacturing base covers 100 thousand SQM, with four production workshops. Thanks to high investment, the plant has an underground drainage system, hardened roads with “four horizontal and two vertical” layout, full pile foundations, and high factory heights. These provide a comfortable working environment for employees and optimal conditions for machine cooling, ventilation, and smoke exhaust.

Zhou Guosheng, Keda Equipment General Manager

“Looking back, choosing a single equipment provider brought us better service. Haitian Precision’s gantry machines meet our expectations in terms of machining accuracy and stability.”

When discussing the new base, Keda Equipment General Manager Zhou Guosheng exudes confidence: “Our factory is embedded with a lot of digital genes. All the Haitian equipment we purchased is equipped with IoT cards, creating a naturally digital factory through interconnection.”

Keda Equipment provides key front-end component processing for its headquarters. In Zhou Guosheng’s view, both Haitian and Keda Equipment solidify the industrial foundation through their front-end manufacturing processes. As industry leaders, Haitian Precision has been Keda Equipment’s top choice from the beginning.

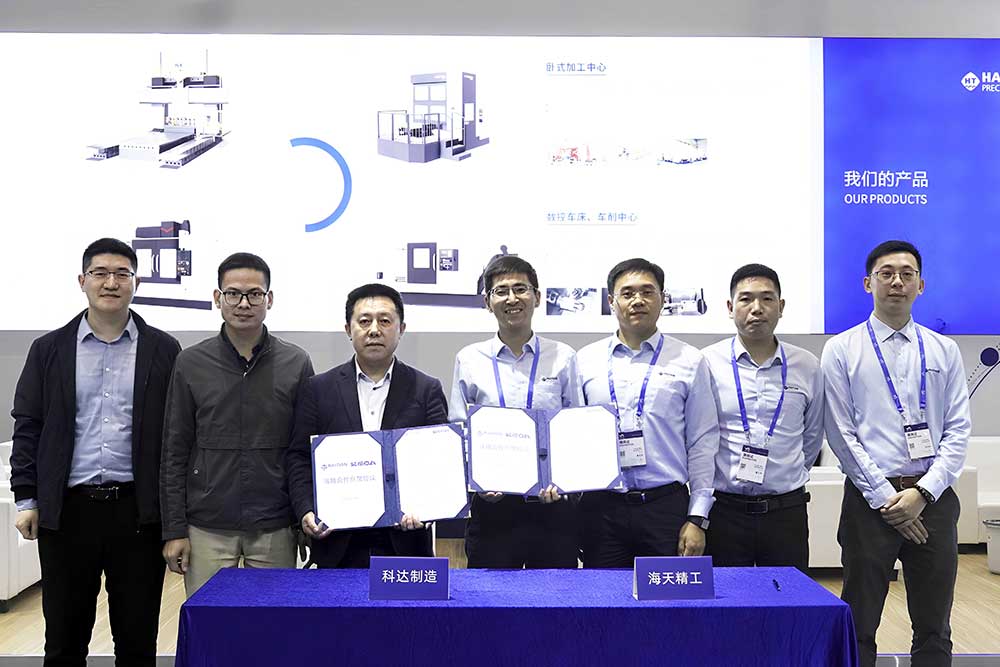

2023 Shenzhen Exhibition Signing Ceremony

Early last year, Keda Equipment signed a contract for 15 large machining centers from Haitian Precision. Zhou Guosheng recalled, “When building this factory, I visited nearly 200 factories across the country, including almost all equipment manufacturing plants in South China. Our facility is the largest gantry machining center cluster in South China.” From installation to commissioning and from production ramp-up to stable production, Haitian Precision provided meticulous service, ensuring strict adherence to the production schedule.

In Workshop No. 3, 15 large gantry machines from Haitian Precision range in size from 8 to 18 meters, featuring strong rigidity, high power and torque, and high stability. They are primarily used for large structural parts such as frames and beams, including large cast and forged parts. All gantries are equipped with the latest system versions, offering user-friendly programming tailored to Keda Equipment’s commonly used parts, saving time and facilitating employee operation during busy work conditions.

The innovative dual gantry machining center further enhances efficiency and is user-friendly for operators, allowing one employee to operate two machines simultaneously, significantly speeding up production. This novel custom equipment serves as a reference model for large structural equipment manufacturing enterprises.

In the new era, supply chains and industrial chains require resilience. Zhou Guosheng is acutely aware that to go further, enterprises must strengthen their foundations and solve critical problems. He mentioned that Haitian Precision’s side milling heads and boring heads break monopolies. When boring deep holes, Haitian Precision’s tools can penetrate thin areas, reducing vibration and improving machining accuracy. Keda Equipment aligns with Haitian Precision’s self-made and self-produced core components, controlling key processes to ensure sustainable accuracy. Keda Equipment continuously promotes technological innovation and iteration of new technologies, driving production capacity to land on its “go global” path.

As Keda accelerates its global expansion and deepens its global layout, Keda Equipment contributes foundational strength. With the increasing share of overseas sales, Keda Equipment has configured a large number of exports, providing related support services for the headquarters and export enterprises. This is also an inevitable trend for healthy and sustainable corporate development. Zhou believes that front-end manufacturing enterprises need to address their shortcomings and possess independent technology to avoid external constraints, thus realizing “China Intelligent Production”.

Keda Equipment’s development reflects the pursuit of manufacturing enterprises for research and development, innovation, and exploration. Guided by the business philosophy of “innovation has no end”, Keda Equipment, along with Haitian Precision, will accelerate the pace of intelligent manufacturing, adding new momentum to the development of the equipment manufacturing industry in South China and beyond.