HUP Series

Precision to the Point

HUP series high rigidity roller guide horizontal machining center. Modern design with advanced international perspective. T-type machine bed, with hanging box layout. 3-axis high rigidity roller guide brings about perfect balance between high precision and high efficiency. It is applicable for a wide variety of rough and finish machining.

Quick Check

X-axis travel range:

2500mm

Y-axis travel range:

1850mm

Z-axis travel range:

1500mm

Max. cutting speed X/Y/Z:

4/4/4m/min

Rapid traverseX/Y/Z:

10/10/10m/min

Max. spindle speed:

2500rpm

Discover

blanc

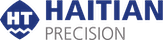

High-power high-torque full gear box structure spindle

High-power high-torque full gear box structure spindle

The large-diameter spindle is supported by long-span precision bearings, which can obtain extremely high precision and rigidity. The large-diameter W-axis spindle box is also optional, which can reduce the original length of the cutting tool when approaching the working piece and thus effectively increase the cutting rigidity

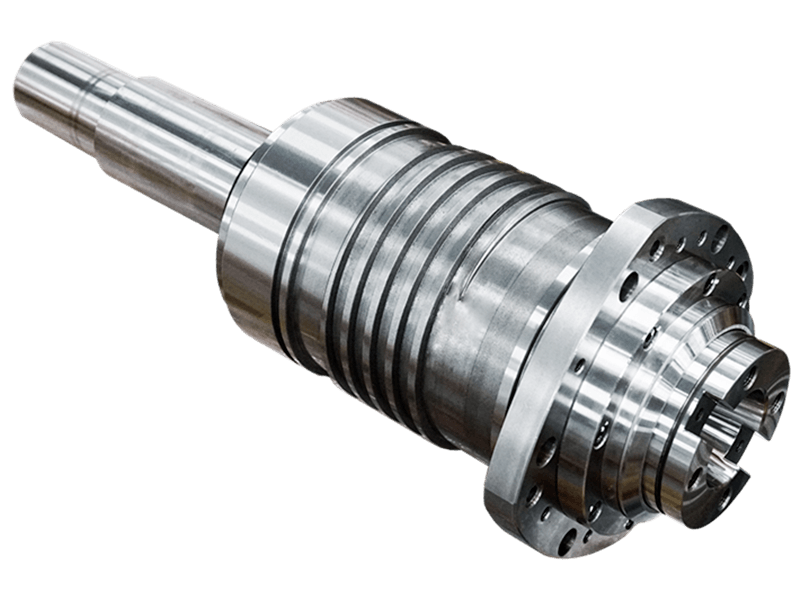

Strong machine bed structure

Strong machine bed structure

The main structure of the machine tool is a T-shaped bed, with hanging box layout and the ribs are arranged inside the bed, which makes the bed structure heavy for better machining rigidity.

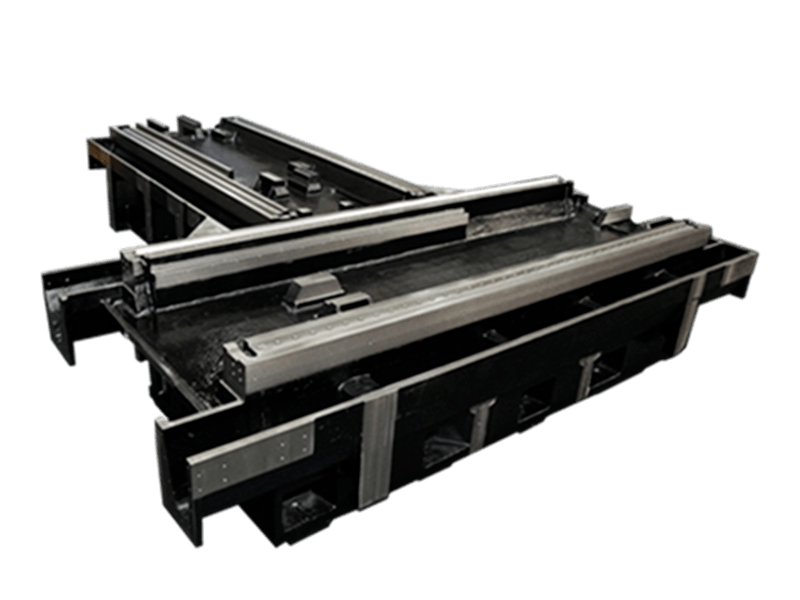

High precision worktable

High precision worktable

Large-diameter chain wheel as standard for higher precise positioning. The worktable clamping adopts a multi-point positioning structure, which effectively reduces the deformation of the worktable while improving the positioning accuracy.

Convenient and efficient double pallet changer

Convenient and efficient double pallet changer

The pallet changer has an open platform for the working piece clamping, which is much easier for the large working piece clamping and further ensure the convenience of working piece clamping and safety of the operator

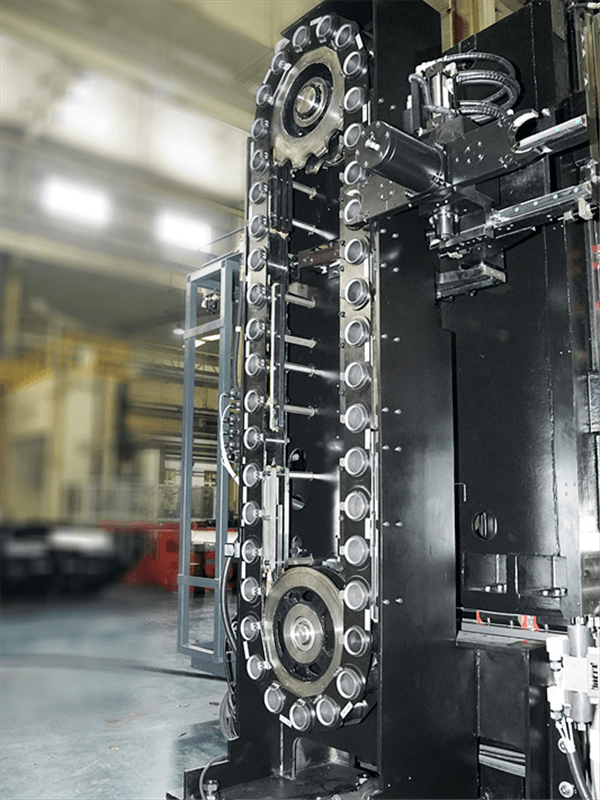

Reliable tool magazine exchange system

Reliable tool magazine exchange system

The tool magazine can provide stable and accurate tool exchange for heavy tools, and the fully enclosed shield at the periphery of the tool magazine allows the operator to safely perform tool exchange and handling.