HISION HTCII CNC Lathes

2023-05-18

Taking the motor as an example, the motor is mainly composed of a shell, front and rear covers, shafts, stators, rotors and wiring harnesses, where the motor shell is a disc shell part that supports the high-speed rotation of the motor shaft and rotor in the motor, and bearings need to be installed in the middle of the motor shell to ensure the normal rotation of the motor, so that the motor shell has the role of sealing and supporting the rotation of the motor shaft.

The motor shell of electric vehicles is usually made of aluminum alloy material to meet the automobile lightweight requirements, and its bore diameter is generally more than 250mm. Its processing difficulties mainly include: first, large diameter holes and IT6 tolerance grade; second, high geometric tolerance requirements for main hole and bearing hole; third, thin-walled shell, which is easy to produce deformation and vibration. Considering that the bearing is to be installed and that the roundness and cylindricity of the bearing chamber are within 0.005mm, we shall prevent clamping deformation and machine tool’s spindle runout during clamping.

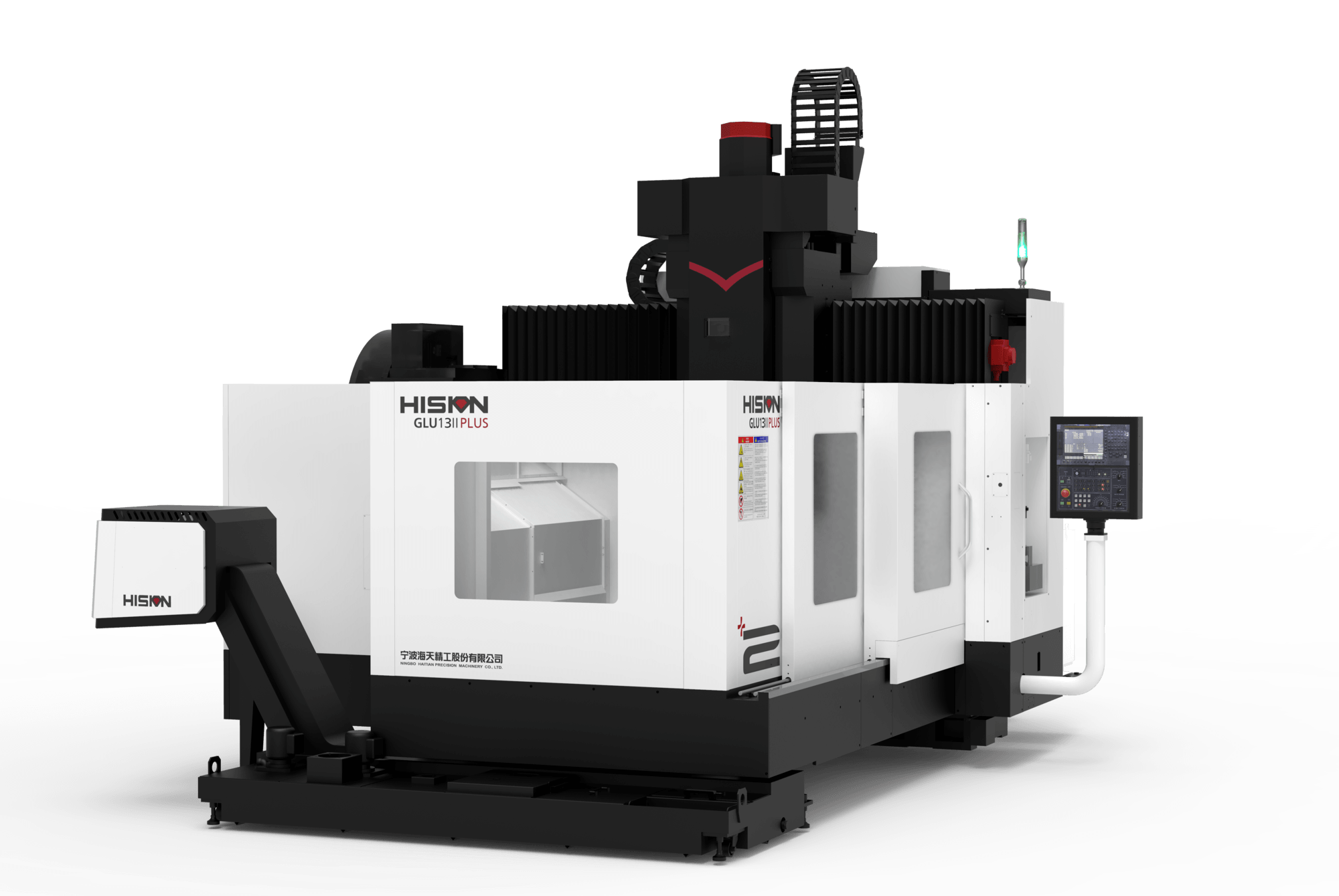

HTCII CNC lathes

The new generation of HTC II CNC lathe adopts integral casting bed structure, reasonable rib cavity arrangement, minimizes vibration, distortion and thermal deformation, and has good thermal stability and long-term precision retention.

Technical characteristics

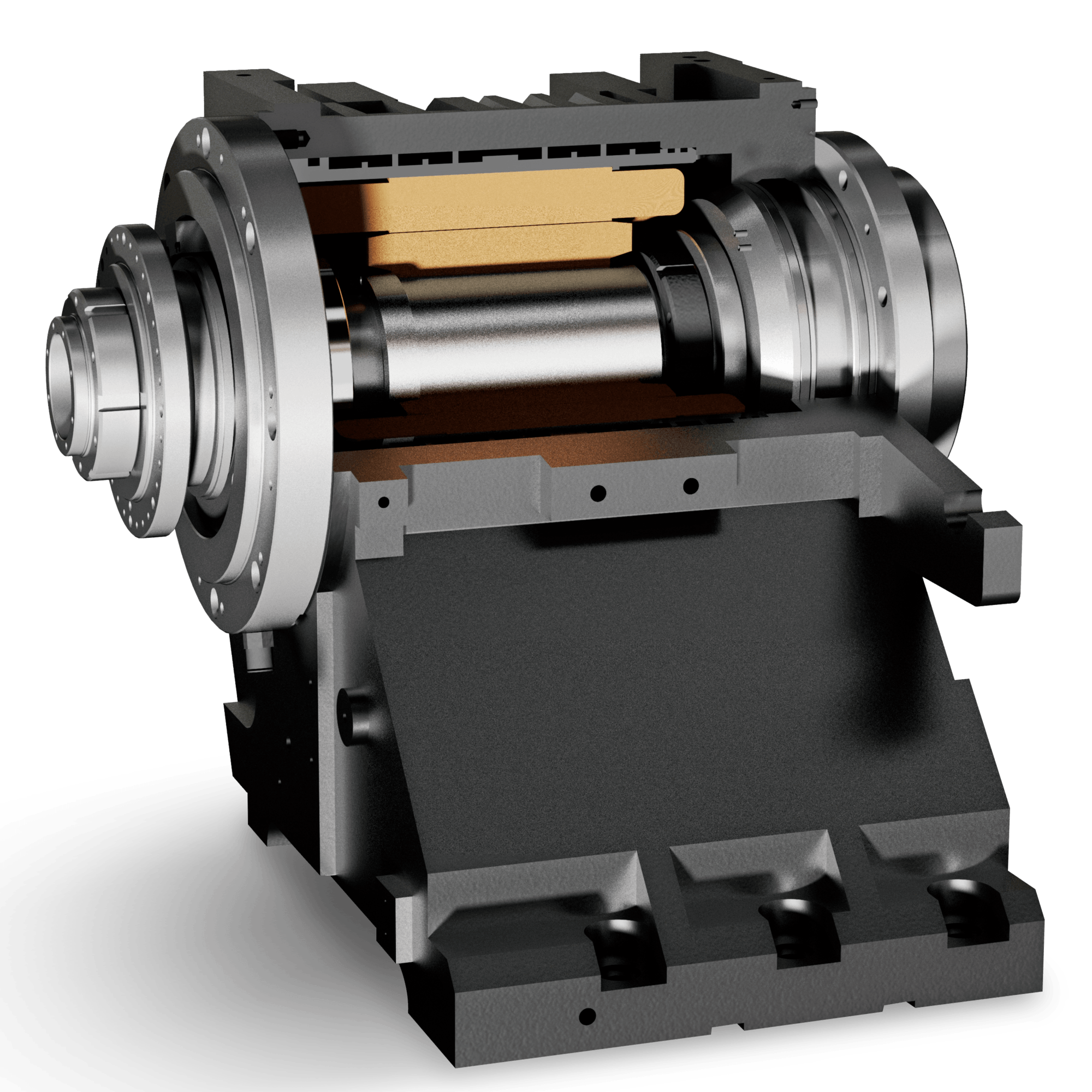

The spindle is directly driven by the built-in motor, and there are no other transmission links, which realizes the “zero transmission” of the machine tool and has good reliability.

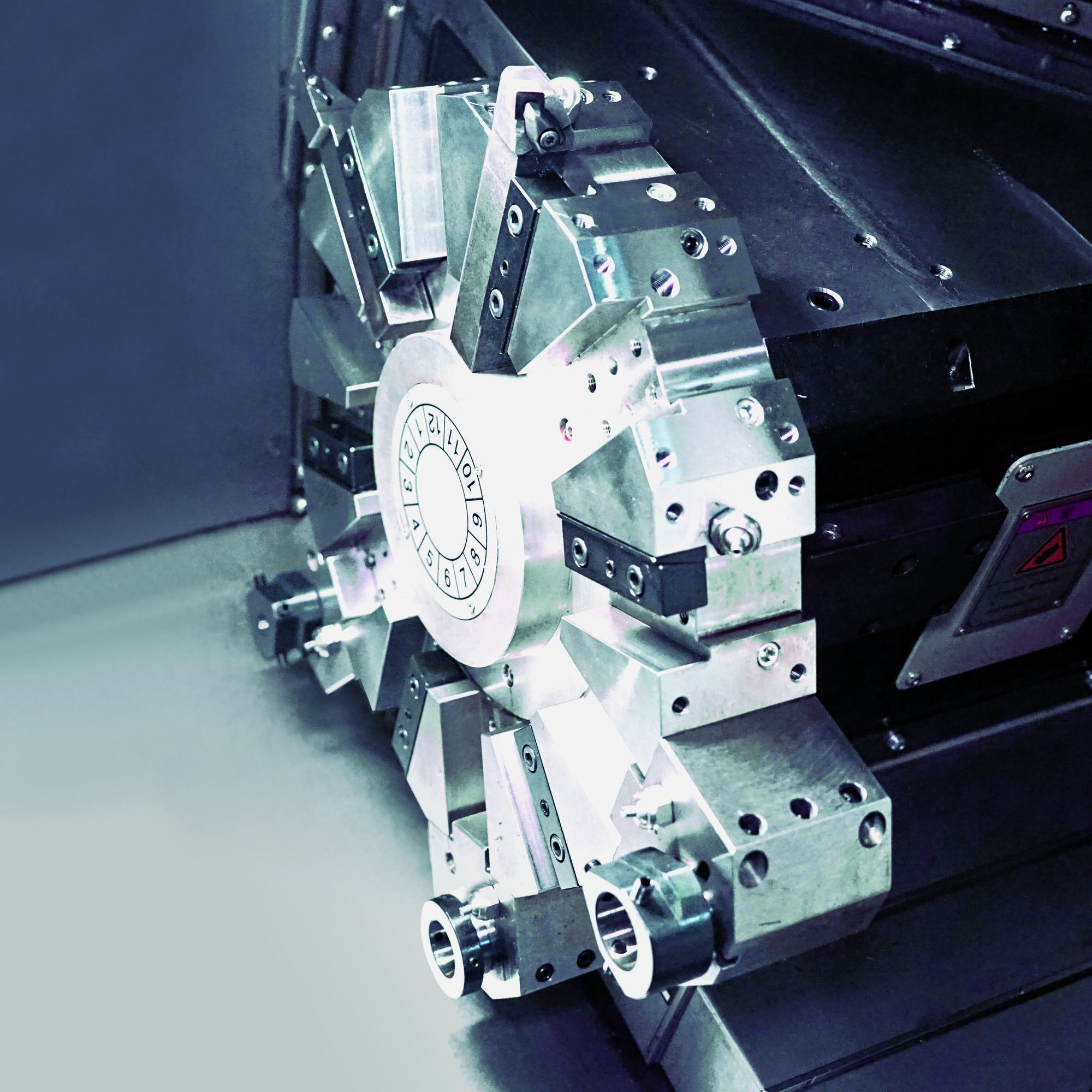

The turret has fast rotation and reliable transmission links to realize synchronous tool change in the process of zero return of the machine tool and improve production efficiency.

Servo motor control and fast response to accurately control the position and tightening force, so as to be easy to achieve automation.