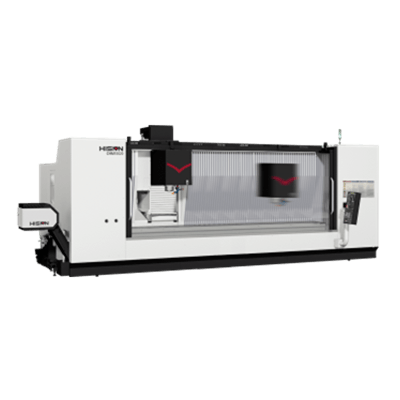

Haitian Precision CHM Long-stroke Vertical Machining Center

2022-07-20

In the production and manufacturing of new energy vehicles, from wheel hubs and chassis to bumpers and luggage racks, various processing technologies and equipment shall be adopted for all these components, among which a large number of parts with powertrain as the core have expedited the further transformation of machine tool processing.

The CHM long-stroke vertical machining center independently developed by Haitian Precision is featured by high speed, large torque and fast feed. A three-axis machine tool with fixed workbench and moving spindle for easier access the workbench is used to easily and efficiently complete the hole surface processing of long parts. At the same time, the arc surface and inclined hole surface of long parts can be processed by configuring the rotating spindle head (B pendulum).

Product features

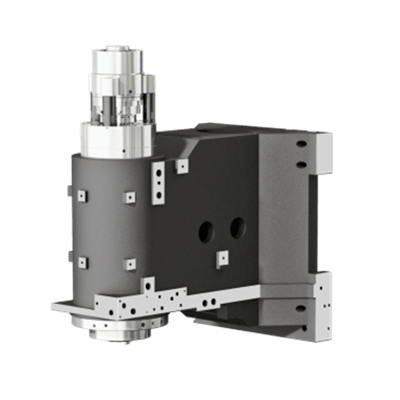

High-speed and high-precision built-in motorized spindle

High precision: built-in DC motor drive, no other vibration source.

Efficient start and stop: “zero” transmission, small inertia, and re-match.

Instantaneous high-power output to turn the stator, 0 to 8,000RPMs, only 0.8s to start.

High precision: built-in DC motor drive, no other vibration source.

Efficient start and stop: “zero” transmission, small inertia, and re-match.

Instantaneous high-power output to turn the stator, 0 to 8,000RPMs, only 0.8s to start.

24 manipulator servo tool magazines

Intelligent tool preparation mode: buffer tool buckle, effective spindle protection.

The automatic protective door of the tool magazine is configured to effectively prevent impurities such as iron filings from entering the tool sleeve of the tool magazine and affecting the machining accuracy.

The tool setting time is 1.2s.

There are 24 servo manipulator tool magazines as standard, and the capacity can be expanded to 30.

Intelligent tool preparation mode: buffer tool buckle, effective spindle protection.

The automatic protective door of the tool magazine is configured to effectively prevent impurities such as iron filings from entering the tool sleeve of the tool magazine and affecting the machining accuracy.

The tool setting time is 1.2s.

There are 24 servo manipulator tool magazines as standard, and the capacity can be expanded to 30.

Design for handleability

The worktable is fixed and the spindle moves, which is more accessible.

The workbench is convenient for loading, unloading and adjustment of workpieces.

The rotatable operation panel is suitable for different operators.

The large and open sliding door structure is convenient for hoisting workpieces.

The worktable is fixed and the spindle moves, which is more accessible.

The workbench is convenient for loading, unloading and adjustment of workpieces.

The rotatable operation panel is suitable for different operators.

The large and open sliding door structure is convenient for hoisting workpieces.

Part processing

Short machining cycle: speed up cutting speed and shorten non-cutting time.

High reinforced thin-walled parts: put forward higher requirements for machining accuracy and deformation control.

Large batch of parts: the equipment has the ability of high-speed, continuous and stable operation.

Short machining cycle: speed up cutting speed and shorten non-cutting time.

High reinforced thin-walled parts: put forward higher requirements for machining accuracy and deformation control.

Large batch of parts: the equipment has the ability of high-speed, continuous and stable operation.