New Second Generation Technology

VMCⅡ Series

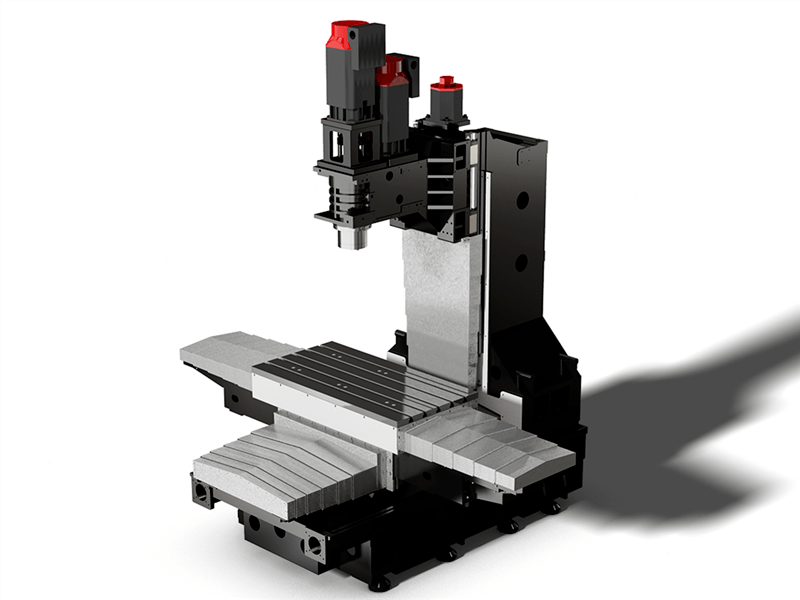

The VMCⅡ series is fixed by A-shaped single column, with mobile structure of worktable, compact overall structure and small floor space and with the design and manufacture conforming to ISO and can complete milling, boring, drilling, tapping and other processes under one clamp. It is configured with standard 8000rpm belt spindle suitable for automobile parts, plastic machinery, construction machinery and other fields.

Quick Check

Cutting speed X/Y/Z

24/24/20 m/min

Rapid traverse X/Y/Z

36/36/30 m/min

Max. spindle speed

8000 rpm

Spindle Power

7.5/11 kW

Spindle torque

71.5/105 Nm

Discover

blanc

High rigidity

High rigidity

The machine bed and main structure are cast in gray cast iron with good rigidity and shock absorption. The ribs are arranged inside the bed, therefore the bed structure is heavy.

High stability

High stability

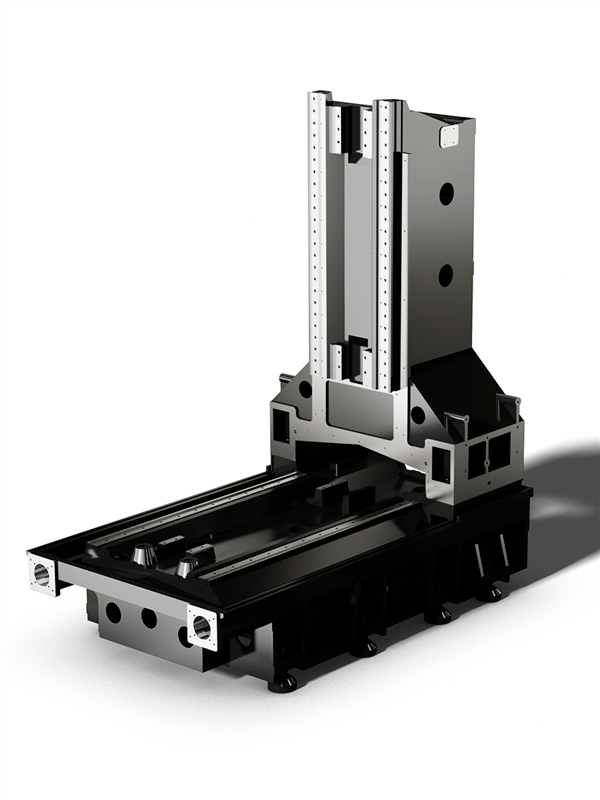

The transverse sliding table and the worktable are all cast in gray iron, of which the transverse sliding table is designed with super long span structure, which can effectively increase the stability of machine tools.

High shock resistance

High shock resistance

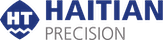

The column has a herringbone structure, and the bottom surface is fixed to the bed by scraping. The inside of the column is the “米”-shaped rib structure with good rigidity and shock resistance, and the bottom is designed as an “A”-shaped structure, which effectively increases the rigidity of the column and reduces the forward tilt caused by the spindle box.

High dynamic response

High dynamic response

The three axes adopt the AC servo motor and the elastic coupling without backlash is directly connected with the lead screw, which directly drives the ball screw to rotate, realizing the reciprocating motion of each axis and fast dynamic response.