Application Lines

Die casting industry solutions

With the further intensification of competition within the automotive industry, there are higher requirements for automotive and parts processing equipment. Machine tools and key technologies such as high-speed technology, intelligent technology, composite technology as well as environmental protection have become key factors in the CNC industry.

Hisions automotive J-Series fully meets customer needs with innovative technology of high efficiency, high precision and high reliability, and incorporates advanced design concepts to create high-end products. The series is equipped with an advanced electric spindle system and a highly dynamic response drive system to make processing faster, more precise, more efficient, and to give environmental protection and energy saving features, to provide customers with specialized solutions.

Camshaft cover processing

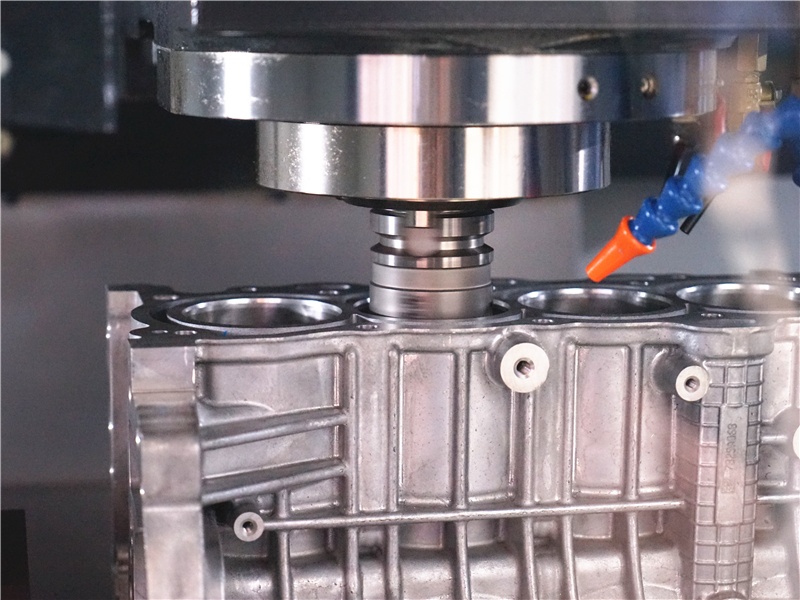

Engine block processing

Car steering knuckle processing

J – Series

High efficiency

Vertical Machining Center

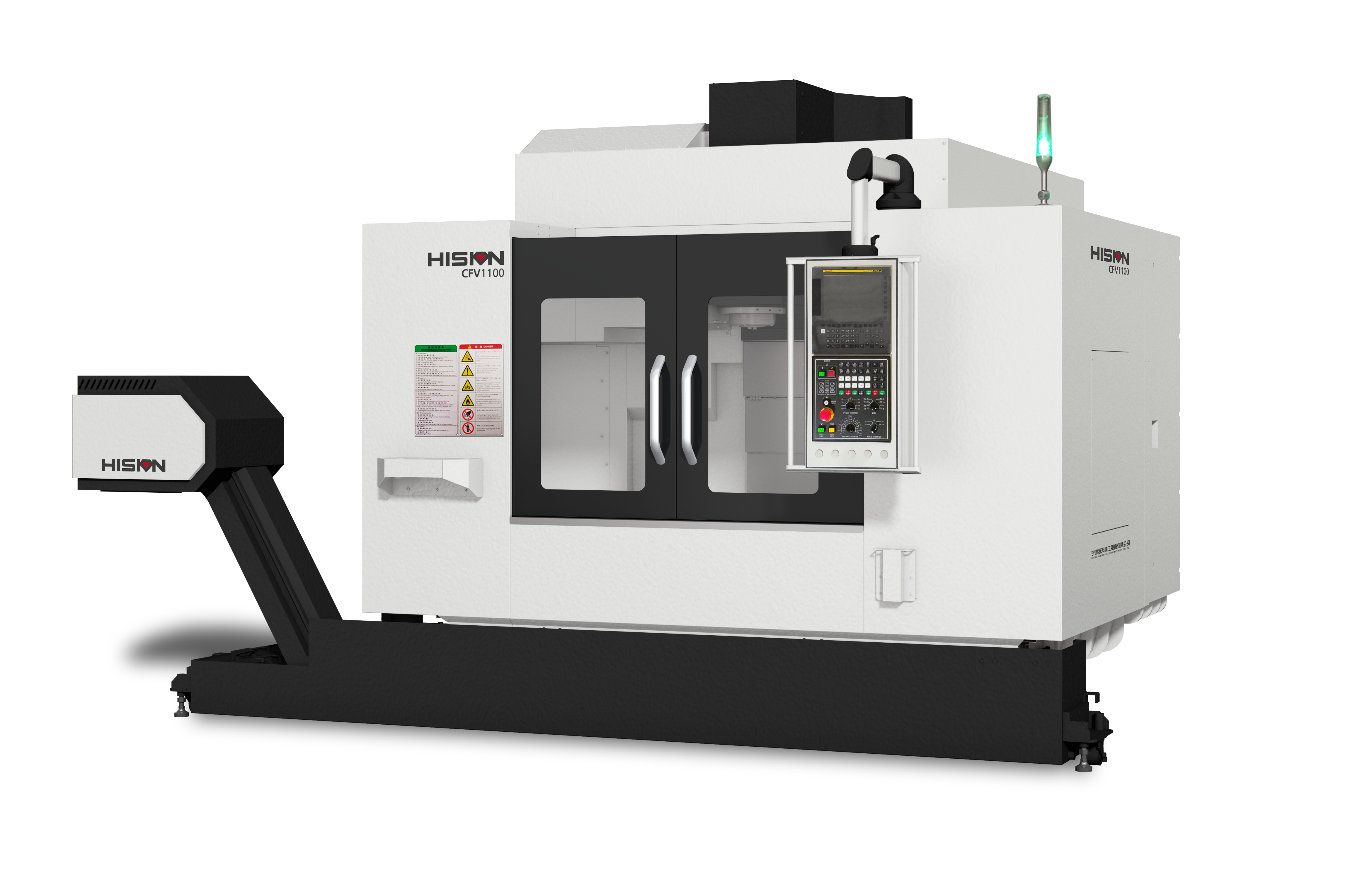

CFV Series

Highly rigid basic components and lightweight moving parts, fully meet the needs of customers.

Vertical Machining Center

CFV Lite Series

Small size, large stroke, spacious processing space, can cope with lightweight large workpiece, multi workpiece.

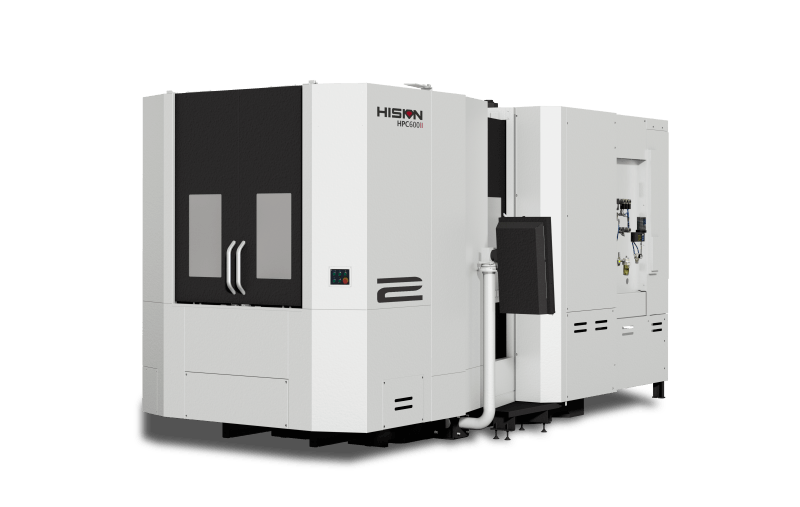

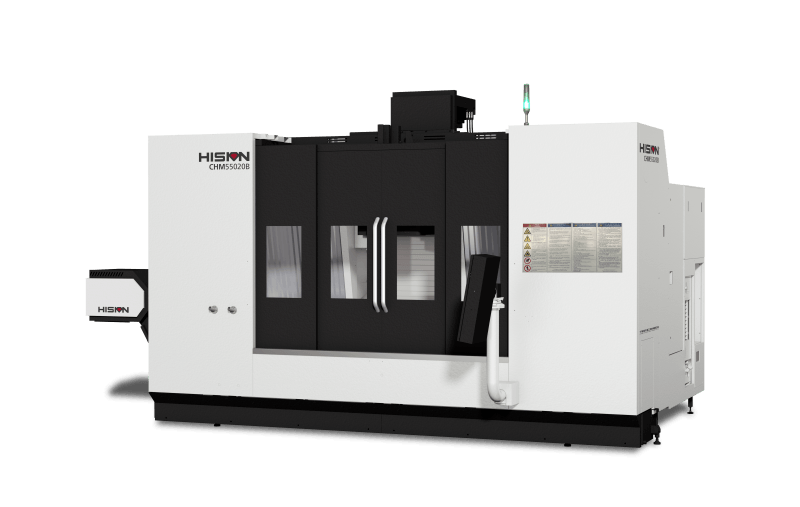

Horizontal Machining Center

HPCⅡ Series

High-speed servo axes and fast-rotating APCs to enable efficient machining.

Vertical Machining Center

CHM Series

The three-axis machine tool with fixed workbench and movable spindle makes it easier to access the workbench.

Gantry Machining Center

BEL/BFL Series

It is suitable for the processing of large aluminum alloy parts, and is suitable for new energy vehicles, rail transit, general machinery and other fields.